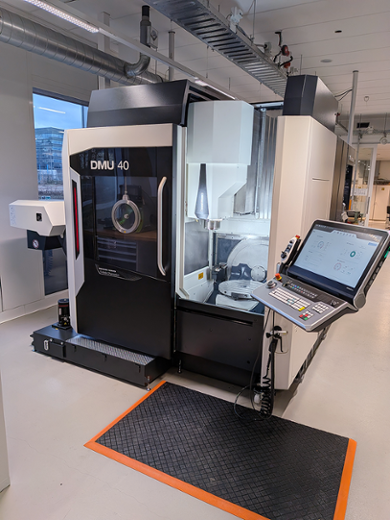

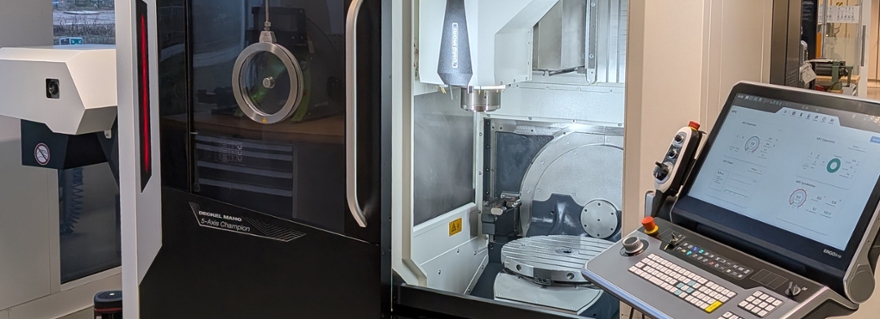

New milling machine at the Fine Mechanical Department: now producing even more complex 3D shapes with extremely high precision

The Fine Mechanical Department has recently expanded its machine park with a universal CNC milling machine. The purchase of this machine is not only an investment in technology, but also in the future of the Fine Mechanical Department, where it is expected to remain in operation for at least 10–15 years.

The new machine mills complex 3D shapes with extremely high precision and can machine a workpiece on five sides in a single cycle. During milling, five axes can move simultaneously around the workpiece (X, Y, Z plus two rotary axes). The machine offers the FMD team new opportunities in the field of CAD/CAM programming.

An example

By way of illustration, this titanium component was recently manufactured by the instrument makers. It forms part of a piezo motor, a motor capable of producing extremely small and precise movements down to the nanoscale. This motor is used in microscopes such as the Scanning Tunnelling Microscope (STM) and the Atomic Force Microscope (AFM), in which experiments are carried out at cryogenic temperatures. This allows scientists to study extremely small structures with great precision, down to the atomic scale.

Would you like to explore whether the Fine Mechanical Department can contribute to your research set-up? Please contact us via our website.

Key features of the DMG DMU 40 Pro milling machine:

- Higher positioning accuracy of up to 4 µm within a build volume of 550 × 450 × 420 mm

- 5-sided and simultaneous 5-axis machining

- Extensive options for cooling tools and materials

- Extensive workpiece clamping options

- An in-machine magazine with 60 different milling tools